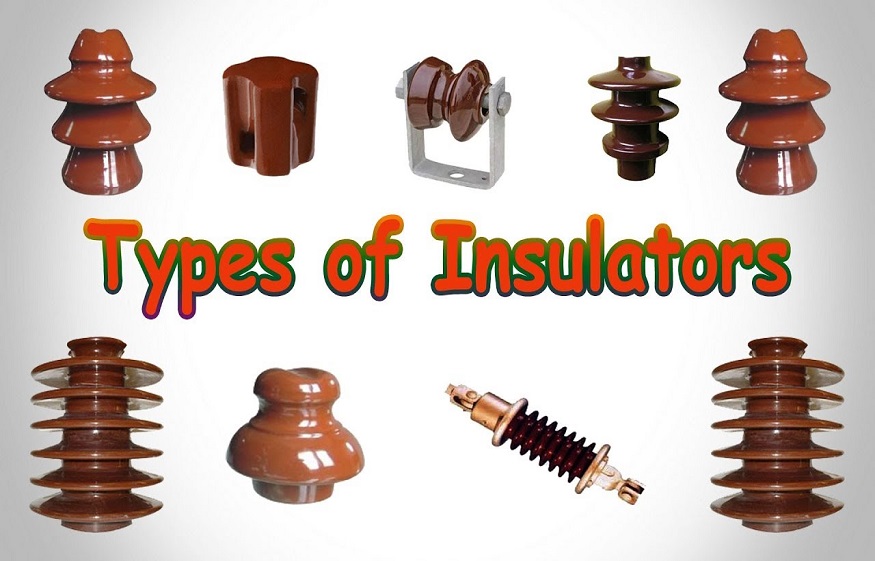

Comparing The Different Electrical Insulators On The Market

Does your home or office have worn out wires? Are they exposed and vulnerable after wear and tear has set in? If so, then you will soon be in the market for a repair solution. Afterall, leaving these wires exposed for prolonged periods is a highly dangerous chance to take. Should these wires come into contact with other electrical conductors or even water and individuals, then major accidents could occur.

Yet, as you set out to do a DIY job, the task is less than straightforward. There are multiple alternatives on market that you will need to decide amongst. In this article, we shall look at these possibilities and discuss which to pick.

Wire Connectors & Heat Shrinkers

For starters, wire connectors (or ‘wire nuts’) and heat-shrink tubing can be easily found in hardware shops at your mall. Cable nuts are commonly insulated plastic caps with inner threading that are made to be turned on to the ends of stripped wires.

Read more: The Best Way to Unwind with Android TV

Heat shrinks are quite frequently located on wires in smaller electrical components and circuits, yet they’re not typically made use of in household or industrial applications where the wire scale tends to be much bigger.

Electric Tapes

One of the major functions and most common uses of electrical tape worldwide is to shield and protect cables and various other connections. However, it’s worth noting that in numerous applications, simply twisting wires collectively and sealing with electrical tape alone is considered an unsuitable splicing approach for meeting rigorous safety requirements.

Similar Adhesive Tapes

Other kinds of adhesive tapes are not typically advised as a replacement for electrical tape when in direct contact with electrical wiring or wiring.This is because they’re made for other applications and have a tendency to lack adequate thermal or insulating properties for electrical usage. As such, this can mean that they rapidly come to be unsafe if deployed incorrectly.

Choosing a Repair Solution

We recommend using wire nuts combined with insulating tape for attaining a totally code-compliant setup. Generally, this combination meets most electrical standards. Since, not all standards are equal, it is important that you always examine any guidelines that might concern the task at hand.

Furthermore, you should note that despite the excellent dielectric efficiency of numerous purpose-manufactured electrical tapes, few materials are truly 100% non-conductive under the right mix of conditions.

Read more: Web Hosting Tips – Pros and Cons of USA Dedicated Server Hosting

Given adequate voltage and current, a brief but wide enough a path to ground, and under the right/wrong environmental conditions, even a specially produced adhesive tape could possibly conduct adequate current to trigger harm.

Be vigilant of the possible restrictions of insulating tapes when used incorrectly or unsafely, and always shut down all circuits to the fullest extent possible before commencing any sort of repair work on them.